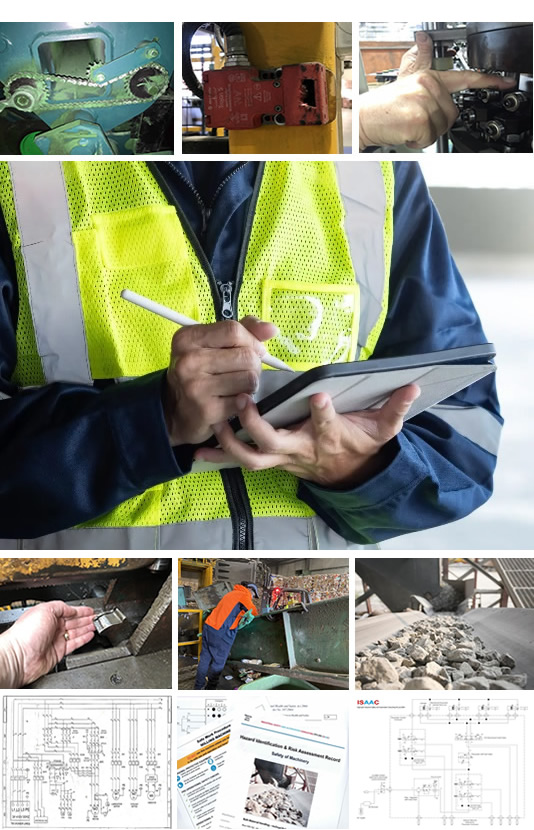

INDUSTRIAL SAFETY AND AUTOMATION CONSULTING PTY LTD (ISAAC)

Hazard Identification and Risk Assessment: Safety of Machinery- Melbourne, Victoria, Australia

ISAAC specialises in machinery risk assessment, focusing on hazard identification and risk evaluation through facilitation, collation, and education for industrial machinery.

In helping our clients grow their skill-set for meeting obligatory requirements of the Occupational Health and Safety Act 2004 (Victoria) , ISAAC specialise in working collaboratively with customers to assist their capture of all knowledge, use, history and experience for the identification of the hazards of the machinery, and establishing AS4024 Safety of Machinery compliant practical risk mitigation strategies. This is an inclusive process that embraces the input of all personnel that have current and or previous exposure to the machinery, including but not limited to machine operators, machine setters, cleaners, supervisors, trades, engineers, OH&S personnel etc.

ISAAC's services are designed to facilitate and provide technical compliment to the findings of a team hazard identification and risk assessment, with the goal of producing a quality record with practical substance, and subsequent fit-for-purpose preventative measures for your machinery derived with your personnel. Our machinery safety skills are comprehensive, TUV certified, and we are vigilant with staying current in the latest legislation, standards, and emerging technologies. We are also independent of directly providing equipment supply and integration services, ensuring untrammeled guidance. However, should a client not have the in-house skill set or capacity to mitigate their risks and integrate resulting control measures, we work to establish them with a network of support to complete their implementation.

We primarily offer our consulting services only within the state of Victoria, Australia, to enable us to maintain our best availability for the demand of local partners, designers of plant, OEM's, suppliers of plant, employers and integrators.

If you require dedicated and quality support in Machinery Safety, whether it's for hazard identification and risk assessment, or in the development and implementation of your risk mitigation strategies, ISAAC is the ideal service provider. Please contact us if you would like to learn more.